19/33kV Single Core Screened & PVC Sheathed (Al Conductor)

Application

These cables are designed to be used for the supply of electrical energy in fixed applications up to the rated voltages at a nominal power frequency between 49Hz and 61Hz., they are suitable for use in distribution installation, electrical power station , they are applied for installation, outdoors, underground where subject to mechanical damage.

Standard

AS/NZS 1429.1

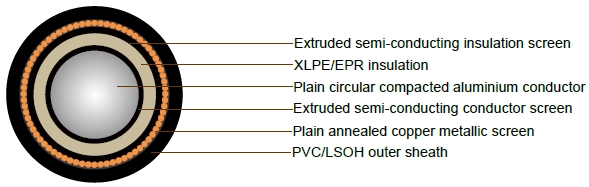

Cable Construction

- CONDUCTOR: Plain circular compacted aluminium to AS/NZS1125 Maximum Continuous Operating Temperature: 90°C

- CONDUCTOR SCREEN: Extruded semi-conducting compound, bonded to the insulation and applied in the same operation as the insulation

- INSULATION: Cross Linked Polyethylene (XLPE) – standard Ethylene Propylene Rubber (EPR) – alternative

- INSULATION SCREEN: Plain annealed copper wire: 3kA for nominal 1 second(LIGHT DUTY) Plain annealed copper wire: 10kA for nominal 1 second(HEAVY DUTY)

- METALLIC SCREEN: Plain annealed copper wire: 10kA for nominal 1 second

- SHEATH: Black 5V-90 polyvinyl chloride (PVC) – standard

- Orange 5V-90 PVC inner plus black high density polyethylene (HDPE) outer – alternative Low smoke zero halogen (LSOH) – alternative

Technical Characteristics

LIGHT DUTY

| Nominal cond uctor area |

Maximum Condu ctor DC resistance at 20°C |

Cond. AC resistance at 50Hz and 90°C | Inductive reactance at 50Hz and 90°C | Insulation resistance at 20°C | Conductor to screen capacit ance |

Maximum diaelectric stress | Current Ratings | |||||

| Trefoil or Flat touch ing |

flat spaced | Trefoil touch ing |

flat touch ing |

flat spaced | Unenc losed In Air |

Buried Direct | Buried In Ducts (c) | |||||

| mm2 | Ohm /km |

Ohm /km |

Ohm /km |

Ohm /km |

Ohm /km |

Ohm /km |

MegOhm. km | uF x km | kV x mm | A | A | A |

| 50 | 0.641 | 0.821 | 0.821 | 0.163 | 0.178 | 0.223 | 18000 | 0.134 | 4.04 | 190 | 167 | 146 |

| 70 | 0.443 | 0.568 | 0.568 | 0.151 | 0.166 | 0.212 | 16000 | 0.148 | 3.81 | 236 | 204 | 177 |

| 95 | 0.32 | 0.41 | 0.41 | 0.143 | 0.159 | 0.204 | 15000 | 0.164 | 3.62 | 287 | 244 | 211 |

| 120 | 0.253 | 0.325 | 0.325 | 0.138 | 0.154 | 0.199 | 14000 | 0.176 | 3.5 | 330 | 277 | 245 |

| 150 | 0.206 | 0.264 | 0.264 | 0.134 | 0.149 | 0.195 | 13000 | 0.189 | 3.4 | 374 | 309 | 274 |

| 185 | 0.164 | 0.211 | 0.211 | 0.13 | 0.145 | 0.191 | 12000 | 0.202 | 3.31 | 430 | 350 | 309 |

| 240 | 0.125 | 0.161 | 0.161 | 0.125 | 0.14 | 0.186 | 11000 | 0.222 | 3.2 | 508 | 405 | 358 |

| 300 | 0.1 | 0.129 | 0.129 | 0.121 | 0.136 | 0.182 | 10000 | 0.242 | 3.11 | 581 | 456 | 402 |

| 400 | 0.0778 | 0.101 | 0.101 | 0.116 | 0.131 | 0.177 | 9100 | 0.267 | 3.02 | 677 | 521 | 459 |

| 500 | 0.0605 | 0.0797 | 0.0789 | 0.111 | 0.126 | 0.172 | 8100 | 0.297 | 2.93 | 787 | 593 | 544 |

| 630 | 0.0469 | 0.0629 | 0.0618 | 0.108 | 0.123 | 0.168 | 7300 | 0.329 | 2.86 | 914 | 674 | 617 |

| 800 | 0.0367 | 0.0507 | 0.0492 | 0.104 | 0.119 | 0.165 | 6600 | 0.366 | 2.8 | 1057 | 759 | 694 |

| 1000 | 0.0298 | 0.039 | 0.0387 | 0.1 | 0.115 | 0.161 | 5600 | 0.427 | 2.72 | 1197 | 841 | 768 |

Cable Parameter

LIGHT DUTY

| Sectional Area of Conductor | Nom. Conductor Diameter | Nom. Insulation Thickness | Nom. Diamete Over insulation | Screen Area on Each core | No. and Diamter of Screened Wires | Nom. Diamete Over Screened Wires | Nom. Overall Diameter | Approx. mass |

| mm2 | mm | mm | mm | mm2 | no x mm | mm | mm | kg/100m |

| 50 | 8.1 | 8 | 25.6 | 20 | 36 x 0.85 | 26.1 | 32.3 | 103 |

| 70 | 9.6 | 8 | 27.2 | 20 | 36 x 0.85 | 27.6 | 33.8 | 114 |

| 95 | 11.4 | 8 | 28.9 | 20 | 36 x 0.85 | 29.3 | 35.7 | 128 |

| 120 | 12.8 | 8 | 30.3 | 20 | 36 x 0.85 | 30.7 | 37.1 | 140 |

| 150 | 14.2 | 8 | 31.7 | 20 | 36 x 0.85 | 32.1 | 38.7 | 154 |

| 185 | 15.7 | 8 | 33.2 | 20 | 36 x 0.85 | 33.8 | 40.4 | 171 |

| 240 | 18 | 8 | 35.5 | 20 | 36 x 0.85 | 36.2 | 43 | 197 |

| 300 | 20.1 | 8 | 37.8 | 20 | 36 x 0.85 | 38.2 | 45.2 | 223 |

| 400 | 23 | 8 | 40.7 | 20 | 36 x 0.85 | 41.3 | 48.6 | 261 |

| 500 | 26.5 | 8 | 44.2 | 20 | 36 x 0.85 | 44.4 | 51.9 | 304 |

| 630 | 29.9 | 8 | 48 | 20 | 36 x 0.85 | 48 | 55.7 | 358 |

| 800 | 34.2 | 8 | 52.3 | 20 | 36 x 0.85 | 52.6 | 60.5 | 428 |

| 1000 | 40.2 | 8 | 59.5 | 21 | 37 x 0.85 | 56.7 | 64.6 | 505 |

Technical Characteristics

HEAVY DUTY

| Nominal conduc tor area |

Maximum Conductor DC resistance at 20°C | Cond. AC resistance at 50Hz and 90°C | Inductive reactance at 50Hz and 90°C | Insulation resistance at 20°C | Conductor to screen capac itance |

Maximum diaelectric stress | Current Ratings | |||||

| Trefoil or Flat touc hing |

flat spaced | Trefoil touch ing |

flat touch ing |

flat spaced | Unenc losed In Air |

Buried Direct | Buried In Ducts (c) | |||||

| mm2 | Ohm/km | Ohm/km | Ohm /km |

Ohm /km |

Ohm /km |

Ohm /km |

MegOhm. km | uF x km | kV x mm | A | A | A |

| 50 | 0.641 | 0.821 | 0.821 | 0.163 | 0.178 | 0.223 | 18000 | 0.134 | 4.04 | 191 | 168 | 146 |

| 70 | 0.443 | 0.568 | 0.568 | 0.151 | 0.166 | 0.212 | 16000 | 0.148 | 3.81 | 238 | 204 | 178 |

| 95 | 0.32 | 0.41 | 0.41 | 0.143 | 0.159 | 0.204 | 15000 | 0.164 | 3.62 | 288 | 243 | 215 |

| 120 | 0.253 | 0.325 | 0.325 | 0.138 | 0.154 | 0.199 | 14000 | 0.176 | 3.5 | 331 | 275 | 244 |

| 150 | 0.206 | 0.264 | 0.264 | 0.134 | 0.149 | 0.195 | 13000 | 0.189 | 3.4 | 374 | 307 | 272 |

| 185 | 0.164 | 0.211 | 0.211 | 0.13 | 0.145 | 0.191 | 12000 | 0.202 | 3.31 | 429 | 346 | 306 |

| 240 | 0.125 | 0.161 | 0.161 | 0.125 | 0.14 | 0.186 | 11000 | 0.222 | 3.2 | 505 | 400 | 353 |

| 300 | 0.1 | 0.129 | 0.129 | 0.121 | 0.136 | 0.182 | 10000 | 0.242 | 3.11 | 575 | 448 | 395 |

| 400 | 0.0778 | 0.101 | 0.101 | 0.116 | 0.131 | 0.177 | 9100 | 0.267 | 3.02 | 668 | 509 | 449 |

| 500 | 0.0605 | 0.0797 | 0.0789 | 0.111 | 0.126 | 0.172 | 8100 | 0.297 | 2.93 | 772 | 576 | 528 |

| 630 | 0.0469 | 0.0629 | 0.0618 | 0.108 | 0.123 | 0.168 | 7300 | 0.329 | 2.86 | 891 | 650 | 595 |

| 800 | 0.0367 | 0.0507 | 0.0492 | 0.104 | 0.119 | 0.165 | 6600 | 0.366 | 2.8 | 1023 | 726 | 663 |

| 1000 | 0.0298 | 0.039 | 0.0387 | 0.1 | 0.115 | 0.161 | 5600 | 0.427 | 2.72 | 1152 | 799 | 728 |

| 1200 | 0.0247 | 0.0327 | 0.0323 | 0.0981 | 0.113 | 0.159 | 5200 | 0.461 | 2.68 | |||

Cable Parameter

HEAVY DUTY

| Sectional Area of Conductor | Nom. Conductor Diameter | Nom. Insulation Thickness | Nom. Diamete Over insulation | Screen Area on Each core | No. and Diamter of Screened Wires | Nom. Diamete Over Screened Wires | Nom. Overall Diameter | Approx. mass |

| mm2 | mm | mm | mm | mm2 | no x mm | mm | mm | kg/100m |

| 50 | 8.1 | 8 | 25.6 | 32.9 | 23 x 1.35 | 29.9 | 34.4 | 125 |

| 70 | 9.6 | 8 | 27.2 | 45.8 | 32 x 1.35 | 31.5 | 36.2 | 150 |

| 95 | 11.4 | 8 | 28.9 | 61.5 | 43 x 1.35 | 33.2 | 37.9 | 180 |

| 120 | 12.8 | 8 | 30.3 | 68.7 | 48 x 1.35 | 34.6 | 39.5 | 200 |

| 150 | 14.2 | 8 | 31.7 | 68.7 | 48 x 1.35 | 36.2 | 41.1 | 215 |

| 185 | 15.7 | 8 | 33.2 | 68.7 | 48 x 1.35 | 37.7 | 42.8 | 230 |

| 240 | 18 | 8 | 35.5 | 68.7 | 48 x 1.35 | 40 | 45.1 | 255 |

| 300 | 20.1 | 8 | 37.8 | 68.7 | 48 x 1.35 | 42.3 | 47.8 | 285 |

| 400 | 23 | 8 | 40.7 | 68.7 | 48 x 1.35 | 45.2 | 50.9 | 320 |

| 500 | 26.5 | 8 | 44.2 | 68.7 | 48 x 1.35 | 48.7 | 54.6 | 370 |

| 630 | 29.9 | 8 | 48 | 68.7 | 48 x 1.35 | 52.5 | 58.6 | 430 |

| 800 | 34.2 | 8 | 52.3 | 68.7 | 48 x 1.35 | 56.8 | 63.4 | 500 |

| 1000 | 40.2 | 8 | 59.5 | 68.7 | 48 x 1.35 | 64 | 70.8 | 600 |

| 1200 | 43.8 | 8 | 63.5 | 68.7 | 48 x 1.35 | 68 | 75 | 680 |